Precision Fabrication Machinery Management

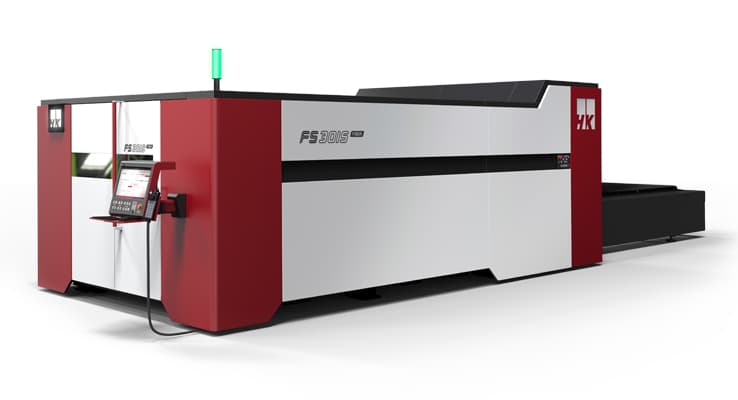

You can give your metal productions a stunning exterior finish with finishing machines. You can do this by using a variety of techniques, including deburring, cutting, and rounding. Equipment calibration has an impact on production speed, finishing ability, and so certain machines are more suitable for a specific project than others.

Our team will provide global supply chain solutions for your business to keep it running efficiently.